Today, it’s a fundamental topic that we’re going to address. That is, the approach that you, the team and the company take to develop new products and technology for your clients. We’re calling it a holistic design. Really, the holistic design is a whole lot more specific than just taking into account every component that goes into a medical device, or focused on the optical imaging development and digital visualization. There’s a number of ways that we can actually describe what it is that we do for our clients.

Q – Justin Starbird: When I say holistic to you and not our approach, what does that mean, not just to you and the team but also to potential clients and prospects?

A – Benjamin Gray: Let me start by giving the definition of holistic in the non-medical terms and more philosophical approach. It’s defined as being characterized by comprehension of the parts of something as intimately interconnected and explicable only by reference through the whole. What the heck does that mean? That’s kind of a mouthful. We use the term holistic with that same philosophical definition, but a little bit of play on words. We know that holistic medicine is also certainly a trending topic these days. What we mean by holistic is more of a systems approach.

That means that we want to understand what the device is trying to accomplish, how it’s accomplishing it, what other parts of a system did they interact with, how a surgeon is going to interpret the information being provided by our systems, and be able to make the right design decisions based upon all that information? It’s not uncommon for contract developers to have basically a box that they’re designing with. They’ve got requirements and they design to that, and they spit it out, and then all the pieces have to fit together.

What we’re looking to do is to try to understand more intimately how well those pieces go together so that we can make the right design decisions, because we realized that, let’s say for example, a camera system that we developed for somebody else’s robotic surgery system, there’s a high level of interaction there. They need to work together seamlessly as one integrated system.

Q: It’s fair to say that you have a systems approach when you’re looking at these projects that you have come across your desk.

A: Yes, absolutely. Really, we approach this from a high level systems development perspective, that then breaks down into more fundamental and disciplined engineering efforts, but are always looked at and reviewed in the light of a holistic system.

Q: When we talk about holistic design and being able to pull the different components together to create, not just the best practice but the best product too, if we’re going to make a checklist of things that we go through in order to start nearing in on where to start, what would we say the first five or seven things are to consider?

A: Well, certainly we need to understand how the device is going to be used. This often starts with our customers who are putting together a users needs or requirements. These are the soft requirements that say something like, “The system needs to be able to look inside of the body.” It’s a very high level. It doesn’t really tell you what to design, but it tells you how it’s going to be used. From there typically, the different levels of requirements and specifications flow down from really high level and generic to more specific.

One of the important elements there is that, we like to work with our clients on converting those user needs to actual true design requirements and specifications, such that there’s not a wall between the user or the clinical side and then our design side. We want to break that wall down.

Q: Would you consider that an advantage in the design and development of products, is that ability to break those walls down?

A: Yes, certainly, because we live in a world where it’s not just one company or one group doing an entire system. Things get broken down into smaller more manageable chunks, hence the nature of the contract design development in manufacturing. Our clients are looking for somebody with expertise in specific areas and our expertise is in visual and digital imaging within medicine. That’s a relatively niche area. There’s a lot that can occur within that space.

We do see it as our responsibility, and one of the services we provide to help link their desires for a clinical application to the technology that then provides visualization to the surgeon. That process is often educating in both directions. We’re learning about how the product is being used and they’re learning about how visual and imaging systems work and how they integrate and work with the rest of their system.

Q: Once you define how it’s going to be used and then you’re able to, as you mentioned, use the advantage of your approach to break down these walls. What comes next as you go through the checklist with the folks so it gets to how it’s used where it’s used. What do you evaluate?

A: Then we’re looking to learn more about their system specifically and the discreet methods of interaction between the system we’re developing and the system that they have as they come together for a complete device. We really want to be able to understand how they’re doing what they’re doing. Even though we’re not really working on the design of their product, it is important that we understand the type of approach. I think after we understand the needs, then understanding the execution on their side is extremely important.

Q: That’s true, in really any business, especially if you’re going to be a service. We come to that from a similar approach, in terms of wanting to make sure we understand everything else that’s going on so that the piece that we play really fits into where the client’s needs and wants are as well.

A: Yes, absolutely. It really depends on the complexity of the service or the product that you’re offering. Even within the work that we see, that does vary, but we have a philosophy at Lighthouse where our goal is to manufacture products, and we can’t do that without being a good partner. Our goal, our desire is to be a good partner for all of our clients so that they see the true value add in the work that we’re doing, both from a design perspective and also a manufacturing perspective. There’s a part of this philosophy and I think this really comes to maybe another item on the checklist.

We like to have weekly recurring periodic meetings with our customers both from a technical and a commercial or business perspective so that we are all in lockstep on the progress of a project and where we stand and everybody’s involved in making critical design decisions as well as other commercial decisions such as schedule versus feature. Sometimes there are performance trade offs that we have to consider versus unit cost or timelines. It is important that we all come together with all the information that we can and make that decision as a group.

Q: In this particular space, there are things that can be customized and there are things that cannot be customized. When you’re looking at a project or you’re evaluating an opportunity, what components are you really looking at, helping be better or improve upon their existing iteration?

A: There are some first order elements that we typically look into. One is always size being in the minimally invasive realm. We’re typically looking for products to get smaller and smaller and smaller. We, first of all, are looking at, “What are the size constraints?” There are certainly performance matters such as resolution or other features that we’re looking at, but we’re also very cognizant of what a client is looking at, for a finished cost of a product or the cost that, as a contract manufacturer, they would purchase from us for. We really look at that like a requirement or a specification because if it doesn’t fit the economic model of our clients, then that doesn’t give us a strong opportunity to manufacture.

Certainly, there are some first-order areas that we look at to help them out with. In a related scenario, one of the things that we try to do is leverage either existing technology or existing platforms that we have. We’re not interested in reinventing technology where it’s not needed. There are times we have to do that, but we try to make that only as needed. Everybody benefits if we can leverage something that works or meets requirements and has a shorter development cost or shorter timeline to get to market.

Q: Because time is money, especially in a situation like this, where if you’re going to spend the resources to create something brand new, typically that’s going to be a whole lot more expensive than taking some off the shelf and making it fit.

A: That’s absolutely correct.

Q: What other factors or components should potential clients consider or even existing clients? What are some of the things that they should look at and questions they should ask themselves before they get to you?

A: It really is quite common that our customers don’t know exactly what they want until we start digging in into the project. That can be looking at requirements and when we start actually putting things down on paper, you start realizing the things you haven’t really considered. This can also happen in the form of just the progress through a project as you get through developing the requirements and you do a first prototype and you test it out, you start to realize that there are things that you may want to change.

I think one of the keys is understanding the development cycle and being nimble and able to make those changes as needed, but yet also maintaining the proper trace ability for developing a medical device. It’s a little bit of a tightrope that we want to walk, but we are able to customize that approach based upon our clients. Some clients are really open to the idea of taking some risk in order to get a really good product. When I say risk, really is more around timeline and development costs, than a safety risk, because of course, everything that we work on is done per medical device development and ultimately, safety tested.

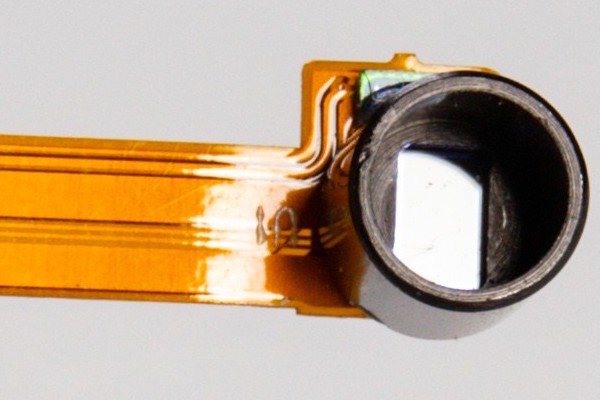

This risk factor really comes more around a commercial risk. We have other customers who really want to do things on more of a straight line. You look at things in terms of cost and schedule and performance risk, and you’re weighing those decisions. I think this is all really important as it ties back to the idea of a holistic design approach. If we talked about that, some of the major components of an imaging system, we have, of course, the optics. Generally, we’ll have an image sensor, we have illumination, we have video processing,we have the physical packaging or mechanics of the system and how it goes together, and then the overall system or architecture of how all of those parts come together.

It’s important that each of those do function to the best level and in conjunction with the other, because you can have four of the five fantastic, but if one of them lets you down, let’s say you just don’t have enough light, but everything else in the system works great, you still don’t have a good image, which ultimately is what we are looking for in these products. Trying to tie some of these elements together. When we start working with a client, we start understanding their needs and their desires. We immediately start formulating an architecture to accomplish that.

We’re looking at what we can use off the shelf or an existing platform or do minor amounts of modification first, and then we start looking at the areas where we have to do custom development, some research and development or even, at times, some invention. Sometimes, this is going out and working with specific suppliers and vendors, sometimes this is in-house work, but the surrounding principle is that we want to look at this as an entire system and how each of the parts affect the other. By having the ability to design, develop and manufacture the entire visualization system, that gives us the opportunity to do that in conjunction with our clients and be fully educated on every step that we take.

Q: It also, not just allows you to be integrated, but it gives you an advantage and it gives your clients the advantage of knowing it’s all coming from one spot. That could be a big win too as they’re evaluating other options and other companies, that the approach and the design and then the manufacturing, all occurs in the same spot. There are folks like you that can oversee the process, from beginning to the end. I think that’s important for folks to realize as well, especially when we’re talking about holistic design because it goes so much further than that.

A: Yes, that’s correct. We like to use the term “turnkey” that we feel like we can provide the maximum value to our clients by offering them the entire service from concept, through design development and manufacturing, they have one point of accountability, one quality system for this portion of the product that’s operating under, and really just simplifying the entire process. Of course, the holistic design approach requires that kind of mentality.