Optical Device Manufacturing

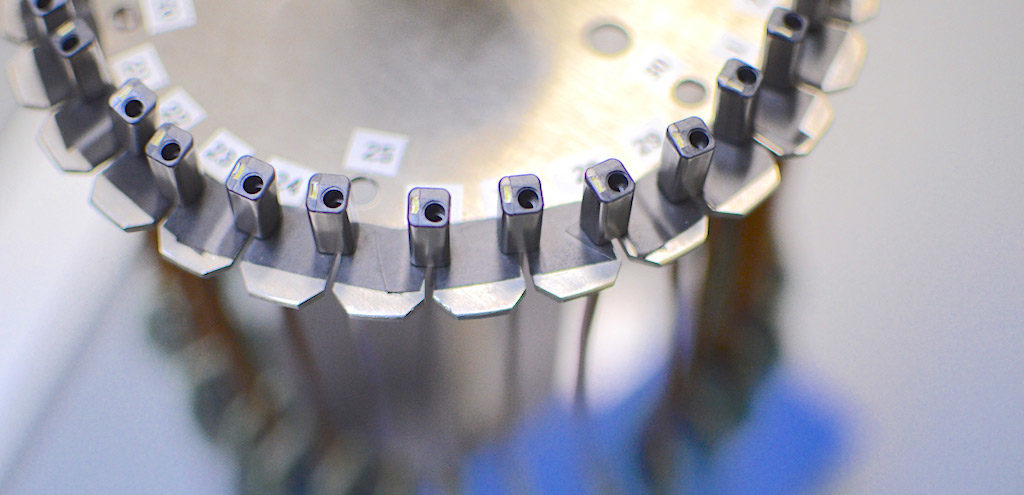

Lighthouse is an FDA registered facility that has been manufacturing optics modules and medical devices with our OEM partners for over 35 years. We have extensive experience with part handling, cleaning, optical alignment, mechanical assembly, soldering, glueing, laser welding and packaging processes. We have the capability to produce complete visualization systems as well as optical sub assemblies. Our manufacturing space includes 3,000 sq. ft of environmentally controlled cleanrooms. Our optical manufacturing team includes supply chain, procurement, quality and production resources. Whether your annual volume is 100 or 100,000, our team can meet your optical contract manufacturing needs.

Optical System Assembly

Lighthouse Imaging is the go-to contract manufacturer for medical optical devices. Leveraging our world-class facility, ISO 13485:2016 certified process, and decades of experience, we will bring your device to reality in our FDA registered facility.

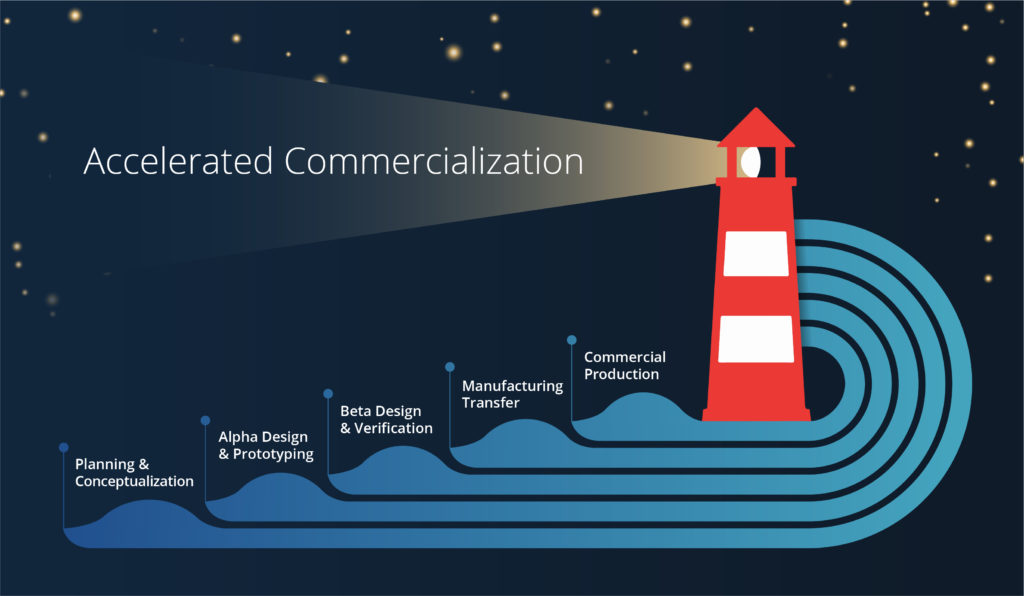

Design for Optical Manufacturing

The Lighthouse Imaging optics product development process incorporates design for manufacturability from day one. We understand that cost and product performance are both important to our clients. We consider cost implications with every major design decision, educate our customers on these implications and make decisions collaboratively. This avoids unnecessary surprises and ensures that our customers needs are met.

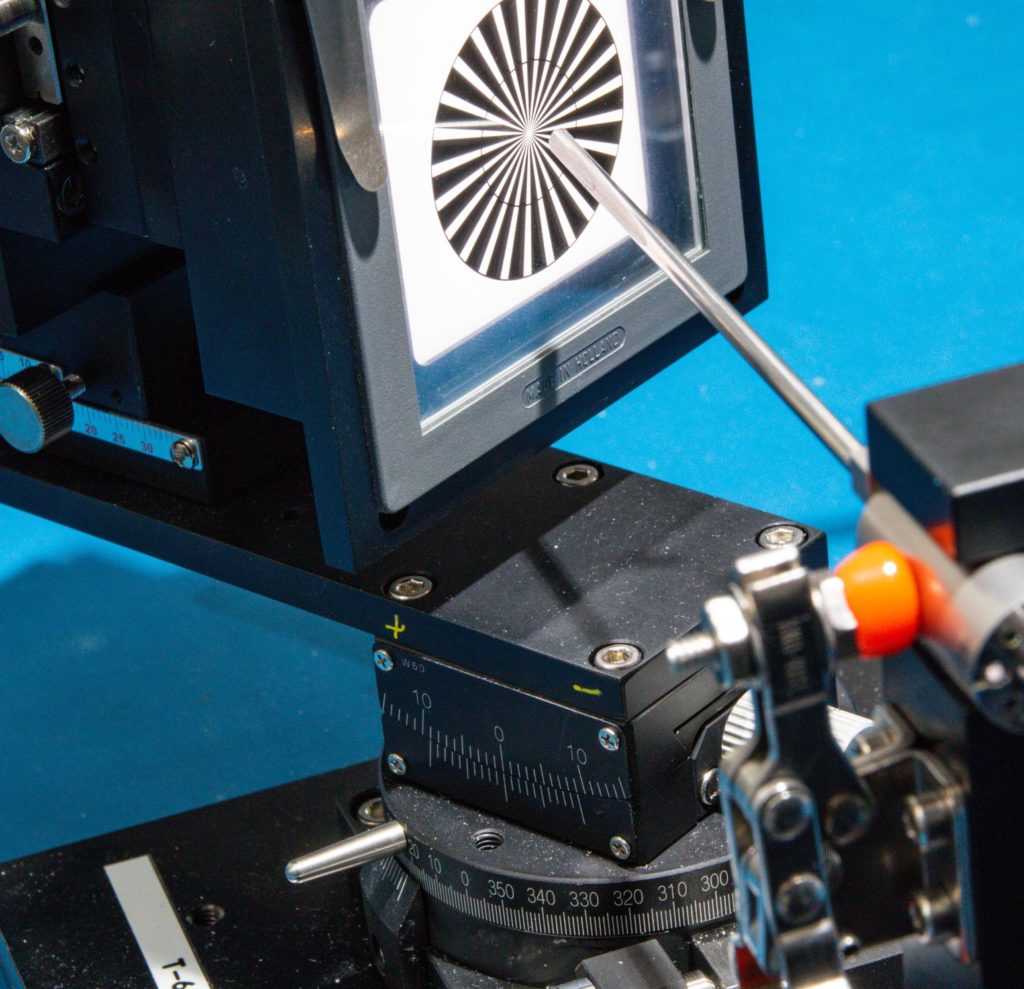

Metrology

Lighthouse invented the first commercial endoscope test equipment over 20 years ago, and has never stopped innovating the methods for data based analytical metrology. Test and inspection of the products we manufacture is designed in from concept, ensuring every specification is met and expectations are exceeded. This is a core belief at Lighthouse.