The Lighthouse Advantage

At Lighthouse Imaging our focus is on taking OEM products from concept into commercialization. We are not interested in prolonging the development phase to generate additional NRE revenue. Instead, we look to accelerate timelines to commercialize our clients products and generate manufacturing revenue as quickly as possible.

About Lighthouse

Since joining forces with Precision Optics in 2021, Lighthouse Imaging has increased capabilities to scale with our customers from design to mass production of optical systems.

Meet the LHI Team

The Management, Engineering and Manufacturing teams at Lighthouse Imaging are passionate about delivering world-class medical optical solutions to our OEM partners. For over 30 years, we have continued to work hard to deliver on our promise of bringing concepts to commercialization. Our world class team of medical optics designers, product developers, and optical contract manufacturers continue to bring Class I, II and III devices to life.

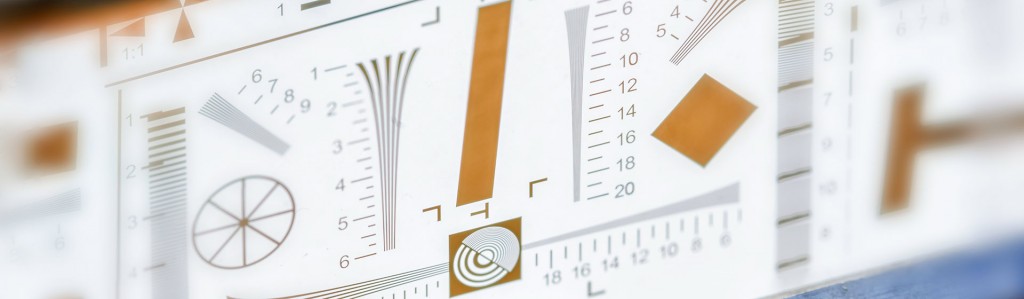

Facility & Lab

Lighthouse Imaging is located in a 13,000 sq. ft. facility with dedicated product development and manufacturing space. We are an FDA registered facility designed to take medical devices from concept through to high volume production.

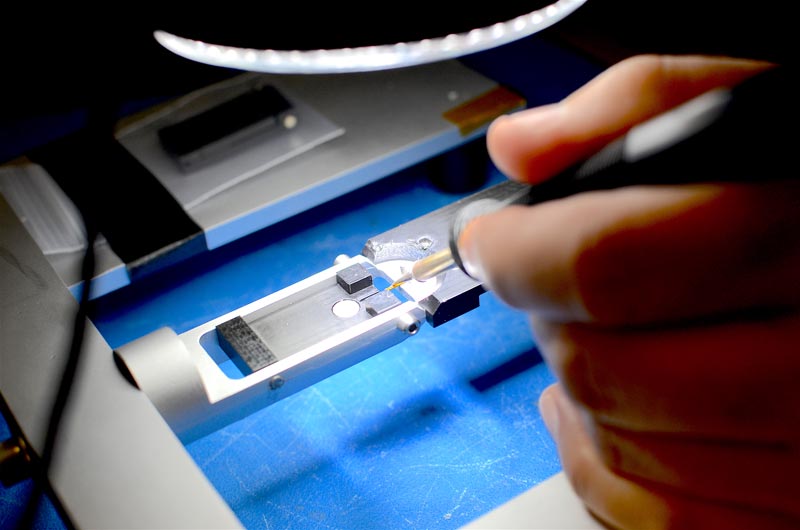

Manufacturing takes place in 3,000 sq. ft. of dedicated cleanroom space operating at ISO Level 7, (Class 10k). Manufacturing is divided into 4 separate spaces, Optics, Sensors, Electronics and Pre-Production/Clinical Rooms which are all ESD controlled.

We also employ a dedicated Quality Assurance lab for incoming material inspection & final product inspection.

Quality Management Systems

Lighthouse Imaging employs a rigorous Quality Management System. We are committed to continually improving the effectiveness of our QMS in accordance with industry best practices. We encourage client engagement with our quality management system.

All QMS conforms to the FDA CFR 820 and ISO 13485:2016 regulations with a commitment to compliance and achieving customer satisfaction.